Prominent Manufacturing Technologies That Can Boost Your Clothing Business

Every industry changes with time and the evolution of technology & efficient machinery take the place of old working formats. The fashion industry is one of those booming niches where technology has a strong influence. Today, numerous cost-efficient, high productive machines are available that produce a plethora of clothing stock in a single go.

If you are an apparel manufacturer Jaipur and are competing in the market, it's essential to consider investing in these manufacturing technologies. Undoubtedly, these advanced technologies will amplify your clothing business and boost your production limits.

Before moving towards the prominent Manufacturing Technologies in the fashion industry, let's take a look at the reasons why machines are in high demand.

High Production Rate: Undoubtedly, the machines don't require any break during production. They only rely on timely maintenance to keep the parts running in good condition. A machine can produce tons of clothes in a single go without taking a halt.

100% Precision: No matter how perfect a craftsman is, there is always an edge of precision that can't be achieved. Even a perfectionist can't make two embroideries 100% identical. However, this isn't the case with advanced machines. The machines work based on the instructions. They follow the same steps and hence produce the exact match clothing stock with 100% precision. In short, with a machine, you never require an inspection to ensure precision.

Low Labor Cost: Traditionally, you require multiple laborers to fulfill the bulk requirement, which requires high labor costs. Today, the laborers are mostly replaced by machines which are just a one-time investment. Only a few laborers are required to manage/handle the advanced machines. This results in low labor costs, high productivity, and ultimately a high-profit margin.

With the introduction of advanced technology, it's now possible to refill the market requirement within a few days without delay. The availability of Private Label Manufacturers has made it possible for brands to fill the gap and maintain their supply without a halt.

Now, let's talk about the modern technologies that have significantly impacted the clothing industry.

Digital Textile Printing: Machines have replaced the old-fashioned working culture. Digital textile printing is one of the modern technologies that has made it possible to print the fabric in a single go. Earlier, one print at a time is the only possibility; that too at a slow pace. However, the speed and efficiency have increased with digital printing. With the help of textile digital printing, the manufacturers can print innovative and exquisite designs. In short, with the introduction of digital printing, magic happens within a short period, and you get fantastic creativity on the fabric.

Stitching Machines: Gone are the days when hand-based stitching was the only option. Today the concept has changed, and highly efficient stitching machines are available in the market. The machines are capable of meeting the bulk orders without compromising the quality.

Yet, a team of QA is always available to match the output with the client’s requirements. Juki is one of the big brands that provide premium quality stitching machines for clothing manufacturers.

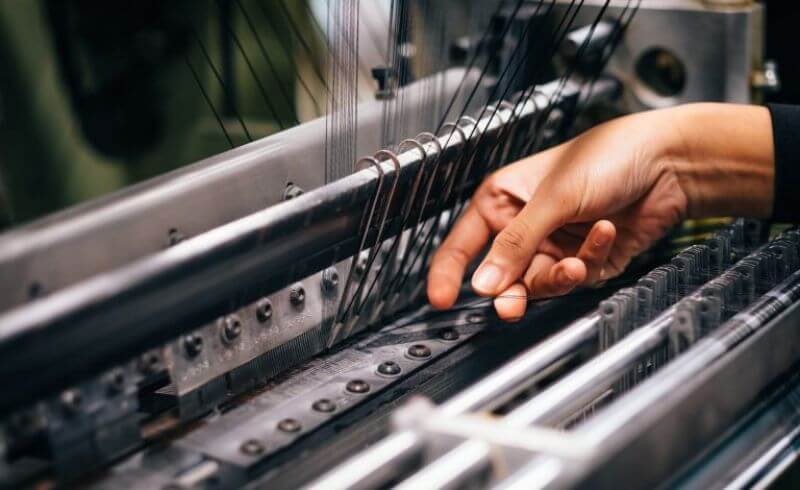

Embroidery Machines: Numerous markets across the globe are still fond of embroidered clothing. High-performance and precision-centric embroidery machines are the only options that can match their needs. Manufacturers have multi-thread embroidery machines that help to take out the beauty from a standard fabric.

Embroidery is a precision-based activity that requires experts. However, the embroidery machines took charge of professional experts and could produce the maximum possible designs in a small tenure.

Textile Bleaching Machine: Bleaching is a chemical process hazardous to laborers (to some extent). The traditional way of bleaching includes the involvement of laborers that causes multiple skin diseases. The concept has today changed, and machines are now responsible for the bleaching process. This has made it possible to maintain safety during work and protect your laborers from skin hazards. The entire process of textile bleaching is computerized that runs with a few instructions.

An expert can handle the machine and bleach textile without physical involvement. Above all, the speed of bleaching has also increased with the use of bleaching machines.

So, these few machines have entirely changed the way manufacturers serve the customers and provide a plethora of clothing options. Apart from introducing advanced technology, the introduction of private label clothing manufacturers has also blessed the brands to serve their customers with quality clothes within budget.

Undoubtedly, technology is growing, and numerous technologies are also merging together to provide us new ways to serve the market needs. Introduction of Artificial Intelligence (AI), Internet of Things (IoT), etc., are some technologies that will revolutionize the clothing industry.

Whether you are a private label manufacturer or a dedicated manufacturing unit of a brand, you can’t survive in the competitive market without adding the above-listed technologies to your workflow.

Related Blog

A Look Into Export Companies In Jaipur: How Are They Driving India’s Global Trade?

Export companies are an important part of any economy as it help global consumers find domestic products of a country....

6 Things Bulk Buyers Silently Judge In Your Clothing Samples That You Must Know About

As a garment manufacturer, you always have to consider what your buyers notice when they’re examining your samples. Especially for...

Learn The Steps On How To Start Your Dream Fashion Boutique Business

Starting your fashion boutique is a dream for many, and for many years, it has remained a dream only....